Mechanical Characteristics ※ The entire machine is designed reasonably, with a simple and compact structure, good mechanical rigidity, and the casting base is widened, with high accuracy and strong rigidity ※ The equipment adopts internationally advanced FANUC and MITSUBISHI CNC control systems ※ It can be manually and automatically controlled on a single machine, and also has the function of manual jog adjustment under automatic control conditions, which is easy to operate ※ High reliability, long service life, low energy consumption, high control accuracy, strong anti-interference ability, fast movement speed, suitable for static mold processing, milling, drilling, tapping of parts, etc

15989519333 (Mr Xu)

Online consultation Message consultation

Main specifications and technical parameters

| Main technical parameters |

||||

| Mechanical specifications |

name |

Specifications |

Company |

|

| trip |

X-axis travel |

1000 |

mm |

|

| Travel Y-axis |

600 |

mm |

||

| Z-axis travel |

600 |

mm |

||

| Distance from spindle nose to worktable |

70-670 |

mm |

||

| Distance from spindle center to column slide surface |

660 |

mm |

||

| workbench |

Workbench size |

1300×600 |

mm |

|

| maximum load |

800 |

kg |

||

| T-shaped groove (number of grooves - size - spacing) |

5-18-90 |

mm |

||

| principal axis |

Spindle speed |

8000 |

rpm |

|

| Main spindle tool holder form |

BT-40 |

|||

| Spindle diameter |

Ø140 |

mm |

||

| Transmission mode |

Belt type |

|||

| Feed rate |

Fast moving speed X/Y/Z |

24 / 24/ 20 |

m/min |

|

| feed rate |

1~8000 |

mm/min |

||

| Machine accuracy |

X/Y/Z-axis positioning accuracy |

±0.005/300 |

mm |

|

| X/Y/Z axis repetition accuracy |

±0.003 |

mm |

||

| motor |

Spindle motor |

7.5 |

KW |

|

| X. Y and Z-axis drive motors |

2.5/2.5/2.5 |

KW |

||

| Oil pump |

DY-YBM-750 |

750W |

||

| Tool magazine (optional) |

Tool magazine capacity |

24 |

branch |

|

| Automatic tool change type |

Circular blade arm type |

|||

| Knife handle specifications |

BT-40 |

|||

| Knife handle pull nail |

45 |

degree |

||

| Maximum tool length |

300 |

mm |

||

| Maximum tool diameter |

Full of knives |

Ø80 |

mm |

|

| Neighboring empty knife |

Ø125 |

mm |

||

| Maximum tool weight |

8 |

kg |

||

| Tool change time |

1.8 |

sec |

||

| Land occupation space |

Mechanical height |

2900 |

mm |

|

| Floor space (length x width) |

2700*2700 |

mm |

||

| Mechanical weight |

8000 |

kg |

||

| Total electrical capacity |

20 |

KVA |

||

| Pressure demand |

0.5 ~ 0.8 |

MPa |

||

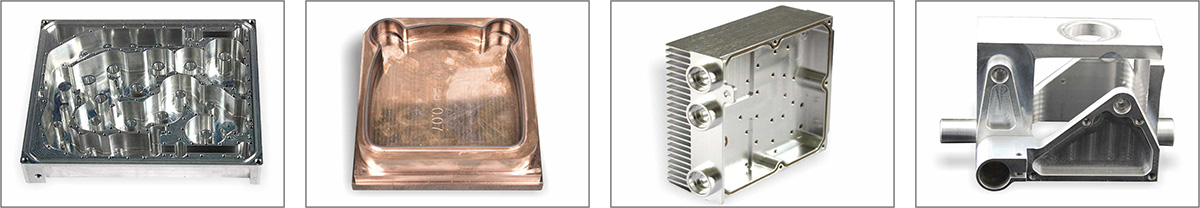

Processing applications Processing application

Precision molds, parts, hardware, automotive, aviation

High rigidity, high precision, double rib structure of the spindle head